Services

IEG is one of regional leaders in specialized engineering and technical services; All products are supported by our on-staff experts and recognized partners, including product support, training, field installation, data collection, analysis and reporting options.

We offer full services and related program support that is not only limited to a specific product or service, but instead we look to understand our clients' needs and develop a best fit program that is a balance of their budget and resources. These are fully scalable programs designed to survive and mature with changing client requirements. At any time, just click on "contact us" and one of our support analysts will contact you to provide a solution and pricing options.

Condition monitoring

CM is the process of determining the condition of mechanical and electrical assets online helping to keep your business running productively and safely by detecting failure potentials in advance. The latest efficient techniques used in condition monitoring are thermal imaging, ultrasound testing, partial discharge detection, vibration analysis and oil analysis solutions, etc. which detects the failure symptoms from different aspects:

- Visual Check, a technique performed based on safety codes to ensure that the standards are complied.

- Thermography, a technique to produce visible images of invisible infrared radiation. We can detect electrical and mechanical potential failures that are invisible to the naked eye.

- Partial discharge, a predictive technique to capture potential insulation degradation ahead of time.

- Ultrasound, a safety precaution technique for identifying failure, mainly air & gas leaks, corona effects and electrical applications.

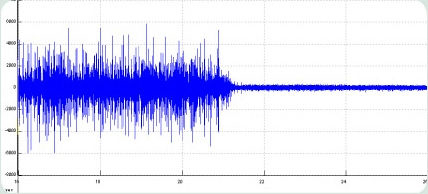

- Vibration, a technique applied on rotating machines to uncover potential issues in early stages.

- Oil testing, a technique that can provide a great deal of information on the condition of equipment as well as providing a leading indicator of what could be the condition of the machine.

Our certified experts in the field of electrical industries will help to locate problems and prevent unscheduled downtime leading to clear results which will help the client to take correct decision and improve overall business safety, productivity and reliability. We cover industrial firms, power utilities as well as other civil locations as malls, hospitals, banks, and schools...

Asset Management

Asset Management involves the balancing of costs, opportunities and risks against the desired performance of assets, to achieve the organizational objectives as per latest best practice covered by ISO 55000.

Asset Management is the art and science of making the right decisions and optimizing the delivery of value. A common objective is to minimize the whole life cost of assets in balanced with other critical factors such as risk or business continuity, which should be considered objectively in this decision-making. IEG will give sufficient support in Asset Management based on the long experience & competency to balance cost, performance and risk.

By adopting Predictive Maintenance technique supported by operational data, we are able to build an integrated digital solution to collect and analyze all input data and give a specific output through a high level of KPIs (Key Performance Indicators). IEG can help in building a health index matrix which linked to company's KPI to track assets and initiate a dynamic asset follow-up along the asset life cycle.

Silicone Coating

Silicone Coating is a versatile silicone sprayable product used to upgrade substation equipment to better voltage insulation; It almost eliminate leakage current on electrical outdoor insulators. It is the most efficient solution to extend the life cycle of assets saving new investments with the luxury of the silicone insulation; The results will resolve the old insulation limitations in substations specially that porcelain insulators are exposed to aging in harsh long term environmental factors. Silicone Coating provides excellent long-term hydrophobicity, electrical characteristics and UV tolerance leading to suppression of leakage current, reduction in pollution, decrease flashover risk and increase service life. Additional benefits of silicone rubber is that it is self-cleaning, reduce maintenance expenditure as in washing and cleaning surface, non-toxic and environmental friendly material. Silicone coating can be applied on site with the dismantling of equipment.

Oil Regeneration

IEG looks for green solutions in most of our services especially if it coincides in better performance and lower cost. Nearly 40-50 % of world's transformers were estimated to be more than 25 years old. This figure is even higher for few countries, with 60 % of transformers reaching the end of their life expectancy of 25 to 30 years. As with all aging equipment, failures become more and more common. Data available from Transmission companies worldwide indicate that the most probable cause for transformer failure is damage of its cellulose insulation.

Ideal solution would be replacement of all old transformers, but this requires considerable investments and will bring disruption of power supply to residential and business customers. Moreover replacement of power transformer is complicated logistical operation and as most of these transformers made on individual order, lead times may be as long as one year. However life of most of transformers can be extended if timely and correct maintenance procedures are applied.

Regeneration of transformer oil is an effective solution that can extend average transformer life by 25 to 30 years.

As a transformer's oil ages, it oxidizes and begins to break down giving rise to by-products that produce sludge, which attacks the chemical bonds that hold the cellulose insulation together. Oil regeneration will remove both the sludge and the sludge forming by-products from both the oil and the cellulose insulation, thereby preventing the production of sludge. Other agents like acids and moisture are also removed which bring back the transformer to almost new condition.

IEG's regeneration process will not only extend the life of your transformer but also will save lot of efforts, cost and specially that regeneration is done on-line without any interruption of supply. This green action is highly recommended since no mineral oil is replaced and then it hadn't to be disposed of, which was time consuming, costly and also had environmental implications.

Integrated Digital Solutions & Utility Modernization

Maintenance Mobile Management (MMM):

It is a unique solution to integrate existing work processes in maintenance and complement the site activities with the head office system. MMM tracks the field activities (On-line or Off-line) with time stamping to allow maintenance manager to control quality and quantity of man-hours spent with digital support to improve productivity and assure strategy.

Digital Operation Management (DOM):

It is a digital tool to control field operation tasks and replaces all paper or verbal operational instructions needed to mange a system, in utilities as well as industries. This middle ware application can be as stand alone or integrated with existing DMS center. DOM tracks the field activities (On-line) with time stamping to allow operation manager to control events and assure system reliability and allow for digital coordination with maintenance reliability decisions.

Optimized Workforce Management

This tailored solution will allow the dispatch engineer to optimize usage of man power available and deliver his duties in optimum performance, high efficiency, improved customer service and low cost.

Power Factor Compensation

IEG has strong partnership with regional factories to develop state of the art medium and low voltage capacitor banks / filters/ reactors. All products were type tested to meet utilities and industries requirements and to suit harsh environmental requirements of the Middle East.

A full-fledged technical set-up backed by the latest simulation software like PSCAD and VHARM are utilized for load flow studies and proposals on power factor improvement and harmonic filtration systems.

The manufacturing range of the capacitor bank and harmonic filters is from 380V to 33000V.

Special application solutions involving dynamic and active harmonic filtration can also be engineered.

OFFERED PRODUCTS:

- Medium and Low voltage capacitor and harmonic filters

- Medium voltage air core and iron core reactors

OFFERED SOLUTIONS:

- Reactive power compensation problems

- Voltage regulator problems

- Harmonic distortion problems

Training

IEG offers specialized training in power distribution best practices in Operation & Maintenance as well as in Asset Management Orientation. These specialized courses are more to be practical and proven to be applicable, effective and worthdoing. Our courses cover the correlation between theoretical facts & site existence, procedures, basic knowledge and practical tools necessary to any field staff to know.